VisualAnalysis performs concrete column design according to the following design specifications:

Columns in VisualAnalysis can have one of four configurations:

Columns with circular bar patterns can be designed using either ties or spirals for the confining reinforcement while columns with rectangular bar patters must have ties. Concrete columns are designed for shear, axial tension without flexure, and combined axial compression and flexure to resist the varying demands along the length of the member. The maximum unity value (demand to capacity ratio) for the member is shown in both the Design View and in the Report View, allowing the user to quickly identify if the member is passing (unity ≤ Unity Success Limit) or failing (unity > Unity Success Limit). In addition to checking the column's capacity, VisualAnalysis checks the reinforcing limits and spacing requirements (for both the longitudinal and confining reinforcing) according to the provisions of the selected design specification. The parameters for columns can be manually adjusted in the tab until a satisfactory design is reached or VisualAnalysis can automatically optimize certain parameters of the design group using the Design the Group button in the Design Ribbon. Design checks are only performed for load combinations that fall under the Strength (LRFD) Design Category (see Load Case Manager).

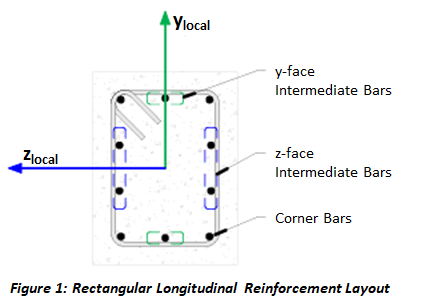

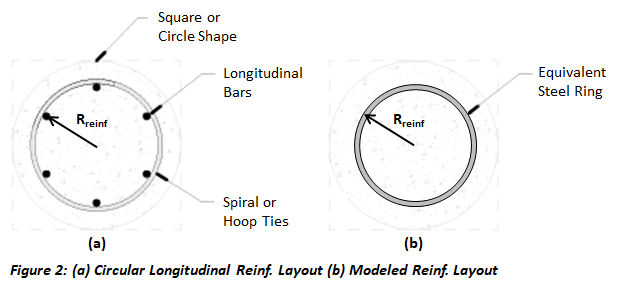

The location and pattern of the reinforcement within a concrete column can significantly affect the capacity of the column. In VisualAnalysis, rectangular reinforcement patterns are modeled using discrete longitudinal reinforcement in the cross-section with the rebar evenly spaced along each face (see Figure 1). A minimum of 4 longitudinal bars are required for the rectangular pattern (acting as corner bars) while the number of intermediate bars on the y-face and z-face are specified by the user. Note that the member's local z-axis aligns with the cross-section's major principal axis (turning on the Picture View filter and the Member Local Axes filter makes it easy to determine the location of the reinforcement within the model). Circular reinforcement patters are modeled using an equivalent "ring" of steel in the cross-section instead of modeling the bars at discrete points in the cross-section (see Figure 2). The radius to the center of ring equals the distance from the center of the column to the center of the longitudinal bars and the thickness of the ring is such that the ring's area equals the total area of the longitudinal bars. Modeling the circular reinforcement as a ring is beneficial as it does not require an assumption to be made for the location of the bars and produces identical interaction diagrams for bending about the z-axis and the y-axis. A minimum of 6 longitudinal bars are required for a circular reinforcement pattern. For both rectangular and circular longitudinal reinforcement patterns, only one bar size can be specified for all of the longitudinal reinforcement.

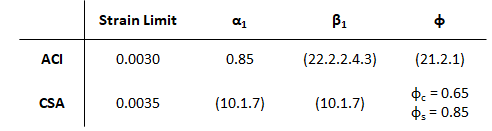

VisualAnalysis develops both the Y-axis and Z-axis interaction diagrams for columns using strain compatibility, equilibrium, the elastic-perfectly plastic constitutive law for steel, and the Whitney rectangular stress distribution for concrete. The neutral axis depth is varied and the factored axial and flexural capacities are calculated. When the longitudinal reinforcement (discrete bars or any part of the steel ring) is located within the concrete compression block, the stress in the steel is reduced by the magnitude of the concrete compression block. In determining the capacity of a column, the ACI and CSA design specifications use slightly different values for the maximum concrete compression strain, the ratio of average stress in the rectangular compression block to the specified concrete strength (α1), the ratio of depth of rectangular compression block to depth to the neutral axis (β1), and the strength reduction factor (φ). The following table shows the values for these limits or provides the applicable code reference.

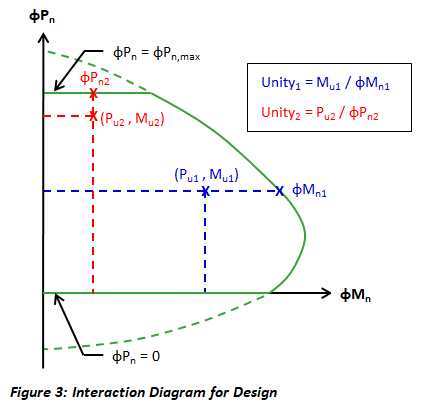

Figure 3 shows a typical interaction diagram that is generated by VisualAnalysis. The interaction diagram is limited by the maximum axial compressive strength at the top (φPn,max) and by φPn = 0 at the bottom (i.e. combined axial tension and flexure is not considered). Therefore, the solid green line in Figure 3 represents the diagram that is used for design while the dashed green lines are disregarded. Both Mu / φMn and Pu / φPn,max are checked when determining the unity value for a column that experiences axial compression combined with uniaxial bending. Mu / φMn will control at low axial loads with high moment (shown in blue in Figure 3) while Pu / φPn,max will control at high axial load with low moment (shown in red in Figure 3).

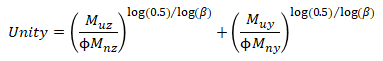

For rectangular and square columns (with both circular and square reinforcement patterns), biaxial bending is considered using the Parme equation to determine the column's Axial Compression + Biaxial Bending unity value.1 The factored moment capacities about z-axis (φMnz) and y-axis (φMny) are determined at the Pu axial load. The Parme equation has the following form:

where:

Muz = Factored moment about the section's z-axis.

φMnz = Factored uniaxial moment capacity about section's z-axis at Pu

Muy = Factored moment about the section's y-axis

φMny = Factored uniaxial moment capacity about section y-axis at Pu

β = User specified Parme equation factor (0.5 < β < 1.0)

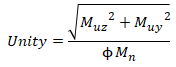

Circular columns have the same interaction diagram for the z-axis and y-axis and at any angle between these two axes. Therefore, resultant of the biaxial moments can be used to determined the Axial Compression + Biaxial Bending unity value of the circular column as expressed in the following equation:

where:

Muz = Factored moment about the section's z-axis.

Muy = Factored moment about the section's y-axis

φMn = Factored uniaxial moment capacity at Pu

VisualAnaysis designs columns for one-way shear along the principle axes taking into consideration the effects of axial load on the cross-section. The effects torsion are neglected for columns. The shear unity check is performed at all result locations along the column and the maximum unity value for the member is reported. Furthermore, VisualAnalysis ensures that the minimum transverse steel area and spacing requirements are met.

The β parameter for shear design is determined using the General Method outlined in the CSA specification. In this method, the longitudinal strain at mid-depth of the cross-section, εx, is computed accounting for the influence of flexure, shear, and axial load. When the cross-section contains at least the minimum transverse reinforcement, the equivalent crack spacing parameter, sze, is taken as 300 mm. Otherwise, sze is calculated with sz = dv and ag = 0, conservatively. The side bars on flexural tension side of the cross-section are accounted for in the calculation of the effective shear depth, dv. Since β is a function of the factored design moment, shear, and axial load which can vary along the length of the column, the shear capacity can also vary along the column's length even when the reinforcement remains constant. Therefore, the unity value is checked at numerous locations along the length of the member and the maximum value is reported. In addition to checking the capacity of the column, VisualAnalysis checks the various detailing requirements in the CSA specification including the proportioning of the longitudinal reinforcement on the column's tension side and the compression side.

VisualAnalysis considers the effects of slenderness for concrete columns using the moment magnifier method. By default, the moment magnifiers for the strong and weak axes of a column are set to 1.0 in the program. The moment magnifiers must be manually entered for both the strong axis (z) and the weak axis (y) of the column. For nonsway (braced) frames, the moment magnifier factor is only δ while for sway (unbraced) frames the combined δ and δs should be used for the magnifier. While effective lengths for the columns are calculated automatically, the user must specify if the column is apart of a sway frame. Alternatively, the effective length factors can be overridden and manually input. The moments are automatically magnified if the slenderness effects are required to be considered per the chosen design specification. The column design length is assumed to be the clear spacing between beams at each end (note: any internal member forces beyond the column design length are ignored).

Several parameters must be defined to design a concrete column in VisualAnalysis. The design parameters are set in the tab when the Design View is selected. After creating a Design Group, choose one of the members that belongs to the group in the Design View to set up the Design Group's Parameters. Since the design parameters apply to all members in the Design Group, it is often best to choose the most conservative condition that applies to any member in the group.

| Concrete |

Specification - The Design Specification used to design the members in the Design Group. High Seismic? - (ACI Only, Use Reduced φ Factors for Members Resisting Earthquake Effects) Enabling this parameter lowers the φ factors as indicated by ACI 318 Section 21.2.4 for members that are designed to resist earthquake effects and are part of a structure that relies on special moment resisting frames or special structural walls to resist earthquake effects. VisualAnalysis relies solely on this parameter in determining whether or not to use reduced φ factors (it does not attempt to calculate whether the shear capacity is greater than the shear corresponding to the development of the nominal flexural strength of the member). Only shear φ factors are influenced by this parameter for design according to the ACI specification. Member Type - Indicates the design shape (Beam or Column). Overstrength? - Causes the Design Group to be designed using overstrength load combinations. Live Load Reduction - If specified, design checks will only consider result cases with the matching live load reduction. Combinations with live load reduction can be created in the . Disable Checks? - Causes selected design group to be omitted from design checks. Check Level - Determines the level of detail reported from design checks. Options are: To Failure (Fastest), Each Limit State, and All (Slowest, but provides the most information). |

| Column Reinforcement |

Reinforcement Pattern - Layout of longitudinal reinforcement (Rectangular or Round). Longitudinal Reinforcement - The size, quantity, and yield stress of the column's longitudinal bars. Confining Reinforcement - The size, spacing/pitch, and yield stress of the column's confining bars. Cover - Clear cover between outer concrete surface and outer surface of ties or spiral. Splice Type - Splice method for main longitudinal reinforcement. Used to determine if the longitudinal bars will fit in the concrete column. Use Metric Bars - Should metric reinforcement be used instead of imperial bar sizes? |

| Axial |

Allow Slender? - Can the columns exceed the KL/r < 100 limit? Parme Equation Beta - The beta coefficient to be used when evaluating the Parme interaction equation for combined compression and biaxial bending (value must be between 0.5 and 1.0). Moment Magnifier Mz/My - The combined delta-ns and delta-s moment magnifier use for the case where sidesway is allowed (unbraced frame). In the case of braced frames, these factors only used delta-ns. Manual Kz/Ky - Allows the user to manually override the effective length factors for the strong/weak axis. Kz/Ky Sidesway? - Choose if the member is apart of a sway frame in the specified direction. |

| Deflections | Strong/Weak - Specifies the type of limit for normal column deflections. |

| Size Constraints | Limit Depth/Width? Allows the design search to 'Fail' if the shape is outside of the Min/Max range. |

To achieve an adequate design, the Design Group's Parameters of the columns in the model can be manually adjusted until all the design checks pass. Alternatively, the built in optimization feature in VisualAnalysis can be used to iterate through some of the column parameters to find an adequate solution using the following process:

1. Create the Columns

In the Model View draw or create the concrete column members.

2. Support and Load the Columns

Define support conditions for the model and apply the service level loads to the members. Set the strength design load combinations in the Load Case Manager.

3. Specify Preliminary Parameters

Set the preliminary column shapes, dimensions, and material properties. Note that concrete columns must have Standard Parametric cross-sections and all concrete columns in a Design Group must have the same shape and dimensions.

4. Analysis and Preliminary Design

VisualAnalysis will automatically analyze the model and perform the appropriate design checks. Simply click on the Results View tab to view the analysis results for the model or the Design View tab to see the design results. VisualAnalysis uses default parameters for concrete column reinforcement that will likely need to be adjusted (see Step 7).

5. Create/Modify Design Groups

VisualAnalysis will automatically create groups for members based on material, orientation, length, and/or cross-section. Alternatively, Design Groups can be created or modified manually as explained in the Groups Category.

6. Concrete Parameters

For each Design Group, select the appropriate design specification, member type, seismic & overstrength parameters, etc. in the in the tab in the Design View.

7. Define Reinforcement

Manually adjust the reinforcement in the tab in the Design View. The layout, size, quantity, and yield strength of the longitudinal bars can be set while the size, spacing/pitch, and yield stress of the member's confining/transverse bars can be set. Upon changing the reinforcement for a Design Group, the unity checks are automatically updated in the Design View.

8. Design the Group

After selecting a concrete column design group, click the Design the Group button in the Design ribbon. In the Design Selection dialog box, choose a parametric type and set the constraints on the dimensions for the cross-section of the concrete member. Click the Optimize Now button to search for various sections and display the unit value for each section using the reinforcement that was defined in the previous step. Note that VisualAnalyis does not vary the reinforcement for each section and only optimized the size of the parametric shape. If a warning stating "demands could not be satisfied" appears, then all the sections within the search parameters have a unity value larger than the Unity Success Limit. Enabling the Return all Shapes feature will provide information on every considered section which may be useful for determining why a section failed or was not optimal.

9. Select a Section

Once the optimization is complete, select a section from the list and click the Accept Design button. Now the unity value for all members in the design group are displayed using the selected section. The tilde symbol (~) in front of the unity value indicates that the unity checks must be validated with another analysis since the member stiffness and resulting load distribution may have changed.

10. Synchronize Design Changes

Click the Synchronize Design button in the Design ribbon to automatically update the model with the new cross-section, re-analysis the model with the new member stiffness, and rerun the design checks with the updated analysis results.

11. Verify Unity Ratios

The final step in the design process is to verify that Unity Ratios in the Design View are less than the Unity Success Limit. If member sizes were drastically changed during the design process, final unity ratios can differ from predicted unity ratios because the analysis results may vary significantly.

Design reports are available by double-clicking on a member in the Design View, by selecting a member and clicking the Report Selected button in the right-click context menu, or by adding tables individually from the Report View. Column reports include both the code checks and the Z-axis and Y-axis interaction diagrams. The results from the strength load cases for each column in the design group are plotted on the interaction diagrams to help the user identify if the columns are passing (all points inside the diagram) or failing (any points outside the diagram). The Concrete Column Parameters used for the Design Group are available with the Member Design Results table by clicking in the table and enabling the Include Parameters setting in the tab.