A bolted end plate moment connection consists of a steel plate welded to the end of a beam section with attachment to a column using rows of fully tensioned high-strength bolts. VAConnect assumes that bolted end plate connections possess sufficient rigidity to maintain the angles between the connected members and behave as fully restrained moment connections (FR) as discussed in the AISC Steel Construction Manual Part 12. VAConnect supports the following configurations using the design procedures of AISC Design Guide 4, Extended End-Plate Moment Connections - Seismic and Wind Applications, as well as the AISC 360-22 design specification and the AISC Manual, 16th Edition.

- Four Bolt Unstiffened (4E)

- Four Bolt Stiffened (4ES)

- Eight Bolt Stiffened (8ES)

Design Considerations

The AISC Design Guide 4 procedure uses a yield-line analysis to design the end plate and column flange to ensure that both remain elastic and thick plate behavior is achieved. With thick plate behavior, the bolts are not subject to significant prying forces

Bolt Force Model

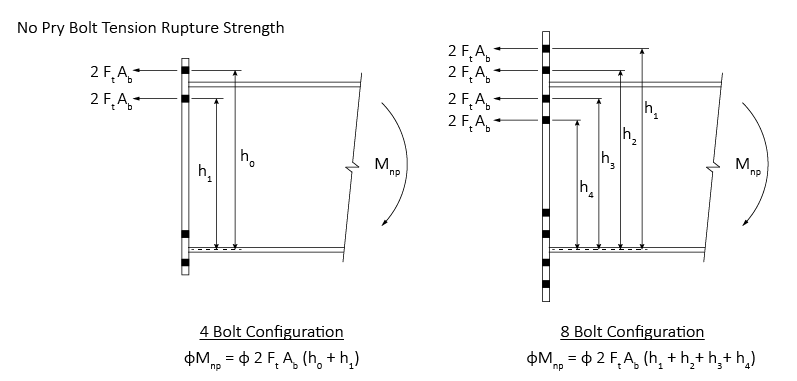

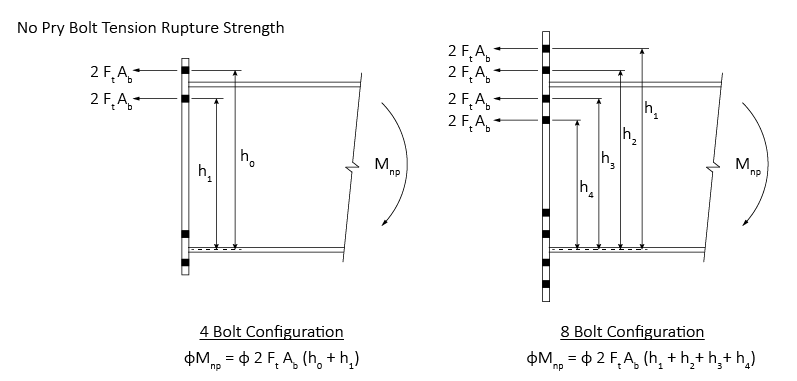

The flexural strength of the connection is based upon the bolt tension rupture and is determined by taking the static moment of the bolt strengths about the centerline of the compression flange as shown in the Figure below. This is termed the No Pry Bolt Tension Rupture Strength.

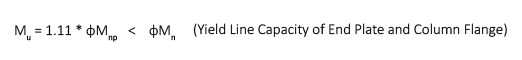

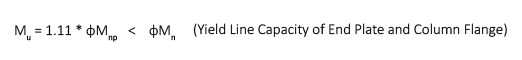

To ensure thick plate behavior, the no prying strength of the bolts must be less than or equal to 90% of the end plate and column flange strength. Another way to state this requirement is that the end plate and column flange strength must be greater than or equal to 111% of the strength of the bolts, as shown below.

Yield Line Theory

Design Guide 4 provides an overview of the Yield Line Theory used to develop the end plate and column flange bending strengths. Per Design Guide 4 the following simplifications have been incorporated into the yield line equations to reduce the complexity of the yield line equations:

- No adjustment in end plate or column flange strength is made to account for the plate material removed by bolt holes.

- The width of the beam or column web is considered to be zero in the yield line equations.

- The width of fillet welds along the flange or stiffeners and web is not considered in the yield line equations.

- The strength contribution from yield lines in the compression region of the connections is neglected.

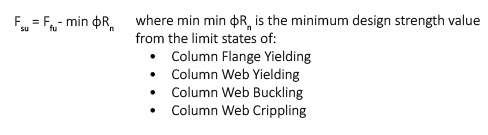

Column Side Design

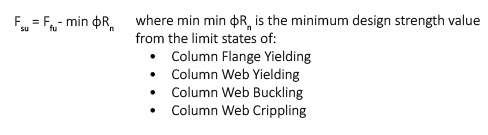

VAConnect checks the limit states of Column Flange Flexural Yielding, Column Web Yielding, Column Web Buckling, and Column Web Crippling to determine if column transverse stiffeners (continuity plates) are required. When the Beam Flange Force (Ffu) exceed the column side capacity (ϕRn) of any of the previously listed limit states, continuity plates are required for the column design. The corresponding Stiffener Design Force (Fsu) that is reported in VAConnect is calculated as follows:

When continuity plates are required for design, additional considerations per AISC 360 and Design Guide 13 are required and are deemed beyond the scope of VAConnect. Additionally, column panel zone checks, such as shear yielding and plate buckling, are beyond the scope of VAConnect, and require further consideration by the designer.

Limit States

VAConnect checks the following limit states for Bolted End Plate connections (refer to the program’s detailed reports for specific code references):

-

End Plate

- Flexural Yield (Yield Line Mechanism)

- Shear Yield (4E Configuration only)

- Shear Rupture (4E Configuration only)

- Bolt Capacity (Shear, Bearing, & Tearout)

- Stiffener Thickness (4ES & 8ES configurations only)

- Stiffener Welds (4ES & 8ES configurations only)

-

Bolts

-

Connected Beam

- Flange Weld (Tension)

- Web Weld (Shear, Base Metal, Tension)

-

Column

- Flange Flexural Yield (Yield Line Mechanism)

- Bolt Capacity (Shear, Bearing, & Tearout)

- Web Yield

- Web Buckling

- Web Crippling

Design Assumptions

VAConnect makes the following design assumptions for Bolted End Plate connections based on AISC Design Guide 4 and AISC Manual Part 12 provisions:

- The bolts are tightened to a pretension not less than that given in the current AISC specification; however, slip-critical requirement are not needed.

- Group A or B high-strength bolts of diameter not greater than 1.5 in. must be used.

- The specified minimum yield stress of the end plate material must be 50 ksi or less.

- All the shear force is assumed to be resisted by the compression side bolts.

- The end plate width effective in resisting the applied moment must be taken as not greater than the beam flange width plus 1.0 inch. This assumption is based on engineering judgment.

- The gauge of the bolts (horizontal distance between vertical bolt lines) must not exceed the beam's flange width.

- When fillet welds are used for the beam flange-to-end plate welds, the welds are designed for the calculated flange force (Ffu) but not less than 60% of the factored tensile yield strength of the beam flange. This recommended minimum weld strength is based on engineering judgment and intended to preclude small weld sizes on comparatively larger beams that may have been sized for stiffness, and to account for the variations in the distribution of flange forces across the weld length.

- The beam web-to-end plate welds in the vicinity of the tension bolts are designed to develop the yield stress of the beam web.

- Only the web-to-end plate weld between the mid-depth of the beam and the inside face of the beam compression flange, or the weld between the inner row of tension bolts plus 2 bolt diameters and the inside face of the beam compression flange, whichever is smaller, is considered effective in resisting the beam end shear. According to Design Guide 4, this assumption is based on engineering judgment; literature is not available to substantiate or contradict this assumption.

- The minimum distance from the face of the beam flange to the bolt centerline (the vertical bolt pitch) is the bolt diameter, db, plus 1/2 in. if the diameter is not greater than 1 in., and plus 3/4 in. for larger diameter bolts.

- When CJP welds are used, weld access holes should not be used.

- A 5/16" fillet backing weld is provided when CJP welds are used at the beam flanges.

- Column continuity plates are not considered effective in resisting bolt tearout.

- For the outer row of bolts, tearout is only considered when the bolts in compression tend to tearout towards the bolts in tension.

- When present, the column cap plate is assumed to prevent vertical tearout of the top row of bolts.

- In the 4ES and 8ES configurations, stiffener geometry is assumed to meet the recommendations of AISC Design Guide 4 Section 2.4 and Figure 2.8.

Limitations

- Permitted beam and column shapes: wide flange "I-Beams"

- Beam is perpendicular to the support column

- Only standard bolt holes are supported

- Only forces in the plane of the connection (shear and moment) can be checked

- A single beam is framing into the support column

- When an unrecognized beam is imported from VisualAnalysis, the beam’s T dimension is assumed to be the depth minus twice the flange thickness (i.e. the fillets are neglected)

- When the beam is located near the top of the column, a column cap plate of the same thickness as the beam flange is assumed to be present

- Only fillet welds and complete-joint-penetration groove weld are allowed at the end plate (partial-joint-penetration groove weld are not supported)

- Weld base metal checks are not included for the beam flange

- The bolt gauge is not checked against the column's workable gauge

- Bolt entering and tightening clearances are not checked