Double Angle Welded Bolted (i.e. welded to the support and bolted to the beam) connections are used to connect steel beams to column or girders. VAConnect is capable of designing these connections to support coped beams and to resist shear loads.

Double Angle Welded Bolted connections are checked per the AISC Steel Construction Manual Part 10 (16th Edition) and AISC 360-22 design specifications. In accordance with AISC part 10, the eccentricity on the supported side of the double-angle connection (i.e. the beam side) is neglected when a single vertical row of bolts through the beam does not exceed a distance of 3 inches from the face of the support. When this condition is not met, VAConnect accounts for the eccentricity using the Instantaneous Center of Rotation method to determine the eccentric bolt group capacity (shear, bearing, and tearout) at the beam side of the double angle and at the web of the beam. Furthermore, VAConnect accounts for the weld eccentricity on the supporting side of the double-angle connection (i.e. the support side). VAConnect also accounts for eccentrically loaded weld groups using the Instantaneous Center of Rotation method to determine the eccentric weld group capacity and for the base metal checks. The “C” coefficients for both the eccentrically loaded weld group and the eccentrically loaded bolt group are included in the detailed reports. This connection closely follows Example II.A-2A of the AISC Design Examples Version 16.0.

VAConnect assumes that the pin (which allows for rotational ductility) occurs at the face of the support. Therefore, eccentricity at the faying surface of the double angles and the support is not considered. VAConnect limits the maximum thickness of the double angle connection to 5/8 inches to allow for flexibility in the connection. While VAConnect allows welding along the bottom of the double angles, it does not allow for welding along the top as welding across the entire top of the angels inhibits the flexibility and necessary end rotation of the connection, according to the AISC Steel Construction Manual Part 10.

VAConnect does not allow double angles welded to the support to be loaded with axial force. According to the AISC Steel Construction Manual Part 12 (16th Edition), double angle connections with welds on the outstanding legs provide minimal strength due to the flexural loading that is applied about the longitudinal axis of theses welds.

Beams coped at one or both flanges are checked per the AISC Steel Construction Manual Part 9 (16th Edition) and AISC 360-22 design specifications.

VAConnect checks the following limit states for Double Angle Welded Bolted Connections (refer to the program’s detailed reports for specific code references):

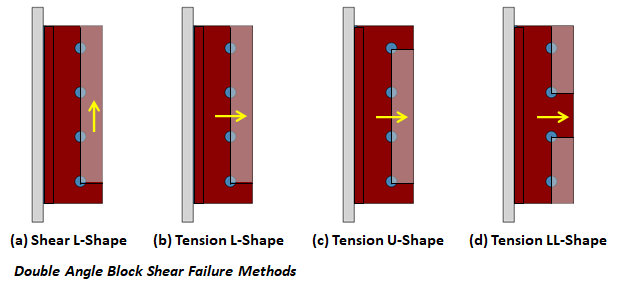

The figure below shows the possible block shear failure methods that VAConnect checks for the double angles. In addition to checking each case (a through d) independently, the interaction for block shear failure from combined shear and tension is considered. While combined block shear only needs to be checked for case a and case b in the figure below, VAConnect conservatively uses the lowest capacity from case b through case d for tension to combine with case a for shear. VAConnect checks the appropriate block shear failure methods and block shear interaction as needed for the web according to the beam's coped condition.