VisualAnalysis performs the design of wood members (beams, columns, braces, etc.) according to the following design specification:

Wood members are designed for flexure (strong axis and weak axis), shear, tension, and compression (parallel to grain) to resist the varying demands along the length of the member. Compression perpendicular to grain (bearing) can also be checked at the start and/or end of the member. When necessary, the interaction of these loads are accounted for in the design checks per the selected design specification. The maximum unity value (demand to capacity ratio) for the member is shown in both the Design View and in the Report View, allowing the user to quickly identify if the member is passing (unity ≤ Unity Success Limit) or failing (unity > Unity Success Limit). In addition to checking the capacity for wood members, VisualAnalysis can check the deflection limits for the members based on the deflection limits set by the user and the Deflection Check load combinations. The dimensions for the wood members can be manually adjusted in the tab until a satisfactory design is reached or VisualAnalysis can automatically optimize the dimensions for the Design Group using the Design the Group button in the Design Ribbon. VisualAnalysis can design members that are made of solid-sawn, post/pile, glued laminated shapes, and some structural composite lumber.

Load duration factors for wood design are specified in the NDS Table 2.3.2 as a function of the longevity of applied loads (e.g. dead loads are assumed to be permanent, live loads are assumed to last up to ten years, etc.). VisualAnalysis automatically determines the load duration factor based on the "load sources" used in the design load combinations. The shortest duration source in the combination us used. The following table shows the duration factors that are used for the load sources (note: impact loads are not considered in VisualAnalysis).

| Load Source | CD |

|---|---|

| Dead, or other loads | 0.9 |

| Live | 1.0 |

| Snow | 1.15 |

| Roof Live Loads | 1.25 |

| Wind or Seismic | 1.6 |

The allowable stresses for Structural Composite Lumber are provided by the manufacturer. VisualAnalaysis currently provides the values for members manufactured by Boise Cascade and Weyerhaeuser. If the desired Structural Composite Lumber or any other wood material is not found, simply create a custom material by clicking the Add Custom Material button in the Material Database dialog box and manually enter the Defining Properties. The following types of custom wood materials can be created: Lumber, Timber, Piles and Poles, Structural Composite Lumber, and Glulams.

Several parameters must be defined to design wood members in VisualAnalysis. The design parameters are set in the tab when the Design View is selected. After creating a Design Group, choose one of the members that belongs to the group in the Design View to set up the Design Group's Parameters. Since the design parameters apply to all members in the Design Group, it is often best to choose the most conservative condition that applies to any member in the group.

Nearly all of the C-Factors can be manually overridden in VisualAnalysis - the Load Duration Factor (Cd) being one of the exceptions. Overriding a modification factor causes the input value to be used in the design checks throughout the entirety of the Design Group and for every load case. Therefore, caution should be used when overriding a modification factor and the results should be double checked. In some instances, a modification factor can have no effect on the design check in a particular Design Group. For example, since the Volume Factor, CV, is only applicable to glued laminated timber or structural composite lumber it will not be used in the design checks for lumber, timbers, or piles and poles.

| Wood |

Specification - The Design Specification used to design the members in the Design Group. Overstrength? - Causes the Design Group to be designed using overstrength load combinations. Live Load Reduction - If specified, design checks will only consider result cases with the matching live load reduction. Combinations with live load reduction can be created in the . Disable Checks? - Causes selected Design Group to be omitted from design checks. This feature can be used to speed up design checks and focus on targeted areas of larger models. Check Level - Determines the level of detail reported from design checks. Options are: To Failure (Fastest), Each Limit State, and All (Slowest, but provides the most information). |

| Bracing |

Lateral Top (+y) - Lateral bracing at the top side of the member (+y). Choose a bracing arrangement. Lateral Bottom (-y) - Lateral bracing at the bottom side of the member (-y). Choose a bracing arrangement. Strong (z) - Brace against strong-axis buckling for columns. |

| Size Constraints |

Limit Depth/Width? - Allows the design search to 'Fail' if the shape is outside the Min/Max range. |

| Configuration |

Has Bolt Holes - Choose if bolt holes in the member should be considered for the axial (pure axial and combined axial + bending) design checks. Bolts are assumed to go through the width of the member (the 'b' dimension). This feature is only valid for rectangular sections. Multi-Piece Lams - Choose if the shear stress value (Fvy) should be reduced to account for a member that is manufactured from multiple piece laminations with unbonded edge joints. |

| Axial |

Manual Kz/Ky - Allows the user to manually override the effective length factors for the strong/weak axis. Kz/Ky Sidesway? - Choose if the member is apart of a sway frame in the specified direction. |

| Beam |

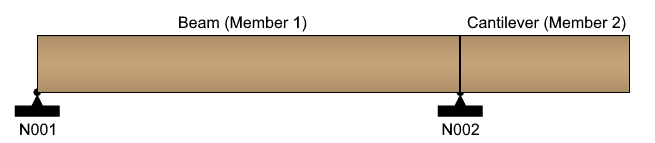

Beam Type - Specify the support conditions for the flexural member (simply supported, continuous, or cantilevered) to determine the effective length (le) of the member used to calculate the Beam Stability Factor, CL. Loading Pattern - Specify how the flexural member is loaded to determine the effective length (le) of the member used to calculated the Beam Stability Factor, CL. Tension Flange on Bottom? - Is the tension flange/side of the beam on the bottom (geometric -y face) of the member? Important: this refers to the shape's XY coordinate system, not the member's YZ system. Check the allowable stress in the design report to verify the setting. Override Lbi? - Override the automatically calculated length between the inflection points of a member. This may be necessary if the length between inflection points extends beyond the endpoint(s) of a model member. This length is used in calculating the Volume Factor, CV. End Notch Type - Indicates whether or not the beam has end notches (tension face or compression face). Refer to NDS 3.4.3.2 for the reductions in shear capacity at notch locations. If a notch type is selected, the notch depth and possibly the notch offset must be specified (see in Figure 3D of the NDS). The depth of the member remaining at a notch measured perpendicular to the length of the member, dn, is the beam depth minus the input notch depth. Bearing length at start - The length of bearing at the start of the member. Bearing length at end - The length of bearing at the end of the member. Check bearing at start? - Should the design members be checked for bearing perpendicular to the grain at the start of the member? Check bearing at end? - Should the design members be checked for bearing perpendicular to the grain at the end of the member? Bearing force direction - The member force direction to use for bearing checks. Shear "@ d" from start? - Calculate the critical shear "@ d" from the face of the supporting member? If Yes, locations at the start of the member, between the face of the support and "d", are not checked for shear. See NDS 3.4.3.1(a) Shear "@ d" from end - Calculate the critical shear "@ d" from the face of the supporting member? If Yes, locations at the end of the member, between the face of the support and "d", are not checked for shear. See NDS 3.4.3.1(a) |

| Deflections |

Strong (dy) - Specify the type of limit for beam deflections in the y-direction. Use Total to include the displacements of the nodes at each end of the element. Weak (dz) - Specify the type of limit for beam deflections in the z-direction. Use Total to include the displacements of the nodes at each end of the element. |

| C-Factors |

Moisture Condition -Select the service moisture condition. This will influence the Wet Service Factor (CM) and the Temperature Factor (Ct). Temp. Range - Specify the extreme temperature condition. This will influence the Temperature Factor (Ct). See NDS 2.3.3. Wet Service Factor, CM - Select how the Wet Service Factor (CM) is used in the Design Group. Reference design values are based on the moisture service conditions specified in NDS 4.1.4 (sawn lumber) or 5.1.4 (glulam). Overriding this factor causes the input value to be used in the design checks throughout the entirety of the Design Group. Calculated CM factors might otherwise vary. Temperature Factor, Ct - Select how the Temperature Factor (Ct) is used in the Design Group. When structural members will experience sustained exposure to elevated temperatures, reference design values should be multiplied by Ct, specified in NDS 2.3.3. Overriding this factor causes the input value to be used in the design checks throughout the entirety of the Design Group. Calculated Ct factors might otherwise vary. Incising Factor, Ci - Select how the Incising Factor (Ci) is used in the Design Group. Overriding this factor assumes the incising criteria in NDS 4.3.8 is met and the input value is used throughout the entirety of the Design Group. Calculated Ci factors might otherwise vary. Repetitive Member Factor, Cr - Select how the Repetitive Factor (Cr) is used in the Design Group. When set to Calculate, the repetitive factor will be uses per NDS 4.3.9. This option is only available for dimension lumber and structural composite lumber. Buckling Stiffness Factor, CT - Select the Buckling Stiffness Factor (CT) is used in the Design Group. This option is only available for visually and mechanically graded dimension lumber and assumes the members meet the criteria listed in NDS 4.4.2.1. Slenderness Limit Increase - KM is a parameter used in calculating the Buckling Stiffness Factor (CT). KM = 2300 for wood seasoned to 19% moisture content or less at the time of plywood attachment. KM = 1200 for unseasoned or partially seasoned wood at the time of plywood attachment. See NDS 4.4.2.1. Curvature Factor, Cc - Enter a Curvature Factor to use adjust the Reference Design Bending Value (Fb) for glued laminated beams only. The input value is in the design checks throughout the entirety of the design group. Pole/pile Treatment - Indicate what type of treatment this pole/pile has. This influences the condition treatment factor, Cct. Pole/Pile Group Count - Indicate how many piles are in a group sharing load. This influences the load sharing factor, Cls. |

| Overrides |

Override CF - Override the size factor (CF). Use only when conditions meet those specified in NDS 4.3.6. Overriding this factor causes the input value to be used in the design checks throughout the entirety of the Design Group. Some factors might otherwise vary. Override CI - Override the stress interaction factor (CI). Used for tapered glulam members, specified in NDS 5.3.9. Overriding this factor causes the input value to be used in the design checks throughout the entirety of the Design Group. Some factors might otherwise vary. Override CL - Override the Beam Stability Factor (CL). Used for reference bending design values (Fb) as specified in NDS 3.3.3. Overriding this factor causes the input value to be used in the design checks throughout the entirety of the Design Group. Some factors might otherwise vary. Override CP - Override the Column Stability Factor (CP). Used for reference design values parallel to grain (Fc) as specified in NDS 3.7. Overriding this factor causes the input value to be used in the design checks throughout the entirety of the Design Group. Some factors might otherwise vary. Override CV - Override the Volume Factor (CV). Used when structural glulam or structural composite lumber members are loaded in bending about the x-x axis, specified in NDS 5.3.6. Overriding this factor causes the input value to be used in the design checks throughout the entirety of the Design Group. Some factors might otherwise vary. Override Ccs - Override the Critical Section Factor (Ccs). Compression design values for piles and poles are based on the strength at the tip. The increase for location of critical section shall not exceed 10% (Ccs<= 1.10) as specified in NDS 6.3.9. Overriding this factor causes the input value to be used in the design checks throughout the entirety of the Design Group. Some factors might otherwise vary. Override Cct - Override the Condition Treatment Factor (Cct). This factor is applied to piles and poles if conditioning other than air-dried was used prior to treatment, specified in NDS 6.3.5. Overriding this factor causes the input value to be used in the design checks throughout the entirety of the Design Group. Some factors might otherwise vary. Override Cfu - Checking this option allows you to override the flat use factor, Cfu. Used when sawn lumber 2 to 4 in. thick is loaded on the wide face, specified in NDS 4.3.7. Overriding this factor causes the input value to be used in the design checks throughout the entirety of the Design Group. Some factors might otherwise vary. Override Cls - Override the Load Sharing Factor (Cls). For piles, reference design values are based on single piles. If multiple piles are connected by force distributing elements so that the pile group deforms as a single element, this factor is used, specified in NDS 6.3.11. Overriding this factor causes the input value to be used in the design checks throughout the entirety of the Design Group. Some factors might otherwise vary. Override Cvr - Override the Shear Reduction Factor (Cvr). Used for the design of non-prismatic members, members subject to impact or cyclic loading, members at notches, or members at connections, specified in NDS 5.3.10. Overriding this factor causes the input value to be used in the design checks throughout the entirety of the Design Group. Some factors might otherwise vary. |

| Material Overrides |

Override Ft (Poles & Piles) - Override the allowable stress for axial tension, Ft. Override Fcp - Override the allowable stress for compression perpendicular to grain, Fcp. Neglect Size Constraints? - Should the Size Checks allow a Beam/Stringer material to be used with Post/Timber shapes? See NDS 4.1.3.3. |

To achieve an adequate design, the size of the members in a Design Group can be manually adjusted until all the design checks pass. Alternatively, the built in optimization feature in VisualAnalysis can be used to find an adequate size for the members in a Design Group. The optimization feature can be used to search for adequate Database Shapes or to iterate through the parameters of a Standard Parametric shape until an adequate shape is found.

1. Create the Members

In the Model View draw or create the wood members.

2. Support and Load the Members

Define support conditions for the model and apply the service level loads to the members. Set the load combinations in the Load Case Manager.

3. Specify the Parameters

Select a preliminary wood Database Shape or Standard Parametric Shape and set the material properties.

4. Analysis and Preliminary Design

VisualAnalysis will automatically analyze the model and perform the appropriate design checks. Simply click on the Results View tab to view the analysis results for the model or the Design View tab to see the design results.

5. Create/Modify Design Groups

VisualAnalysis will automatically create groups for members based on material, orientation, length, and/or cross-section. Alternatively, Design Groups can be created or modified manually as explained in the Groups Category.

6. Define the Parameters

For each Design Group, set the wood parameters (design specification, overstrength, etc.) in the in the tab in the Design View. Also, adjust the bracing, size constraints, configuration, axial, beam, deflections, C-factors, overrides, and material overrides for the Design Group as needed.

8. Design the Group

After selecting a wood Design Group, click the Design the Group button in the Design ribbon. In the Design Selection dialog box, choose the search type (Database or Parametric) and set the number of shapes to be returned from the optimization. For a database search, choose which database is to be searched and the category of shapes (Dimensional Lumber, Glulam, Post, or Timber) that are to be searched within the database. Also, set the size constraints if needed. For a Parametric search, select the parametric type (Rectangle or Circle) and specify the search range (Start and End) and the Increment for each parameter of the shape or choose to hold the parameter constant. Once the search parameters are set, click the Optimize Now button to search for various sections and display the unit value for each shape. If a warning stating "demands could not be satisfied" appears, then all the shapes within the search parameters have a unity value larger than the Unity Success Limit defined in the Preferences. Enabling the Return all Shapes feature will provide information on every considered section which may be useful for determining why a section failed or was not optimal.

9. Select a Section

Once the optimization is complete, select a section from the list and click the Accept Design button. Now the unity value for all members in the design group are displayed using the selected section. The tilde symbol (~) in front of the unity value indicates that the unity checks must be validated with another analysis since the member stiffness and resulting load distribution may have changed.

10. Synchronize Design Changes

Click the Synchronize Design button in the Design ribbon to automatically update the model with the new cross-section, re-analysis the model with the new member stiffness, and rerun the design checks with the updated analysis results.

11. Verify Unity Ratios

The final step in the design process is to verify that Unity Ratios in the Design View are less than the Unity Success Limit defined in the Preferences. If member sizes were drastically changed during the design process, final unity ratios can differ from predicted unity ratios because the analysis results may vary significantly.

Design reports are available by double-clicking on a member in the Design View, by selecting a member and clicking the Report Selected button in the right-click context menu, or by adding tables individually from the Report View. The notation used in the reports is similar to that used in the NDS specification. In general, allowable stresses use an upper case 'F', such as Fb for bending, Fv for shear, etc., while actual stresses use a lower case 'f'. The wood design reports in VisualAnalysis are highly customizable. To control what is included in a report, simply click on a table in the report and adjusted the settings in the tab. The Extreme Rows feature is particularly useful to produce concise reports of only the controlling cases or to produce detailed reports that display every design check that is made. When this feature is set to Show All, the reports may become excessively large which can be controlled by adjusting the Conciseness feature. The reports for wood design include both a summary of the parameters input for the Design Group and tables that included the various design checks. These tables have the following columns:

| Column Name | Description |

|---|---|

| Member | The member's name. |

| Section | The member's cross-section (e.g. Rectangle 2 x 10). |

| Offset |

This is the distance from the 'start' end of the member. The number and locations of offsets are as defined in the performance settings in VisualAnalysis. |

|

Result Case |

The result case that is used for the design check. |

| Demand/Capacity | These columns varies depending on the type of design check (fb & Fb, fv & Fv, etc). In most cases these values are used directly in the unity check. |

| Code Reference | The controlling equations or provisions from the chosen design specification. For example, "3.3-1" refers to the equation in the NDS specification while a reference like "3.6.3" refers to a section in the specification. |

| Unity Check | The unity check value for this particular member, load case, and offset. Unity checks are calculated as the absolute value of an actual stress divided by an allowable stress [ASD] or as the ultimate stress (factored) divided by the design stress (factored) [LRFD]. |

| Details | Intermediate values and other information which can be helpful for validating results. |

VisualAnalysis makes the following assumptions or has the limitations described below: